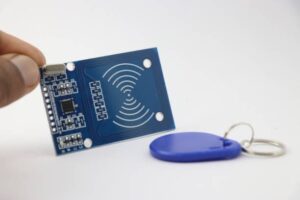

Unlike barcodes, RFID tags don’t require physical contact to read. It makes them a powerful innovation for businesses that must verify items, equipment or inventory.

Passive RFID labels and inlays typically run for less than a dollar per tag. Specialised RFID stickers cost can be a bit more expensive.

Cost-effectiveness

Many businesses are interested in RFID technology for inventory management and workflow automation, but the upfront fixed costs are significant. Understanding the cost-effectiveness of RFID is critical to ensuring that it delivers on its promise and returns a positive ROI for your business. The two main costs to consider are tag and reader costs and implementation and maintenance costs.

Many businesses are interested in RFID technology for inventory management and workflow automation, but the upfront fixed costs are significant. Understanding the cost-effectiveness of RFID is critical to ensuring that it delivers on its promise and returns a positive ROI for your business. The two main costs to consider are tag and reader costs and implementation and maintenance costs.

The cost of RFID tags varies, depending on the product type, whether the tag is passive or active, and its packaging. A passive 96-bit RFID EPC inlay (chip and antenna mounted on a substrate) costs 7 to 15 U.S. cents. Still, the total cost of the tag may be higher due to other factors, including shipping and handling costs; if the tag is embedded in a label or has additional features, such as extra-long battery life or sensors, the price increases.

RFID technology can also reduce operational costs by eliminating the need for manual form filling and replacing outdated spreadsheets with automated data collection systems. It can also avoid transcription errors and duplicated records by scanning items automatically and uploading them to a central database.

RFID can also help companies reduce out-of-stocks by providing visibility into inventory movement. In addition, the system can help them control shrinkage and track lost items. Moreover, RFID can save employees time by eliminating the need to count items manually. It can benefit hotels and restaurants, where counting assets is tedious.

Inventory management

RFID (radio-frequency identification) tags have been a hot trend in inventory management. They are poised to disrupt the market by offering superior visibility, increased accuracy, reduced RFID stickers cost and more. They can be used in distribution centres and warehouses to streamline processes like shipment verification, counting, inventory check-ins, and reducing shrinkage. They also help reduce manual errors by allowing users to scan multiple items simultaneously. These benefits have led top retailers to invest in RFID inventory systems.

An RFID management system uses microchips and RFID readers to track products. The microchips can be encoded with different data types, which the RFID reader then captures. This information is then transmitted to a host system that manages the inventory and can be used for a variety of purposes.

Security

Whether your company uses RFID for inventory management or to track the location of a piece of equipment in a data centre, it’s important to weigh the risks against the benefits before deploying this technology. RFID chips can provide many advantages, including improved accuracy compared to barcodes; reduced labour costs, as items can be scanned automatically; enhanced security, as the chip’s unique identifier can be encrypted and programmed to prevent counterfeiting or unautunauthorisedss to information; real-time tracking capabilities, as tags can send a signal to the reader every 30 seconds; and durable design, as they are typically resistant to physical damage.

The cost of RFID tags varies depending on the type and quantity purchased. Generally speaking, passive tags are the cheapest, costing as little as 20 cents each. These tags contain an encapsulated UHF chip and an adhesive backing. In addition to these basic tags, specispecialised for specific industries or environments may use different materials and cost more.

The cost of RFID stickers has fallen dramatically in recent years, making them a viable solution for many distribution centres and warehouses. Basic passive RFID labels can be as low as $0.10 to $0.20 each, and prices can drop even lower when bought in bulk. SpeciSpecialisedive or active RFID tags designed for specific use cases can be more expensive. Engineers are developing ways to affix RFID tags so that they don’t obstruct function or risk being destroyed when an item is used.

Passive RFID tags must be encoded before they can store and transmit identifying information, which can take just a second or two. The encoder is a small device that uses radio or electromagnetic waves to write a unique number into an empty tag or label, emitting its identification signal. Rewritable and updatable tags, which allow retailers to change the information stored on a tag, can be more expensive.